Sicotronic is

What is intelligent

Peak load management?

...and why is it important?

More and more kitchens are switching from gas and fossil fuels to all-electric appliances. However, this is increasing the challenge of making optimum use of limited electricity capacity - especially in commercial kitchens and hotels. This is precisely why Sicotronic developed.

Our intelligent load management system monitors the energy requirements of all kitchen appliances and controls the power distribution so that overloads are avoided and peak loads are reduced. The system ensures that each appliance receives the exact amount of energy it needs - when it needs it. without unnecessary or simultaneous peak loads from the power grid.

Presentation of the Sicotronic

Peak load management system

%

Reduction up to

How Sicotronic works

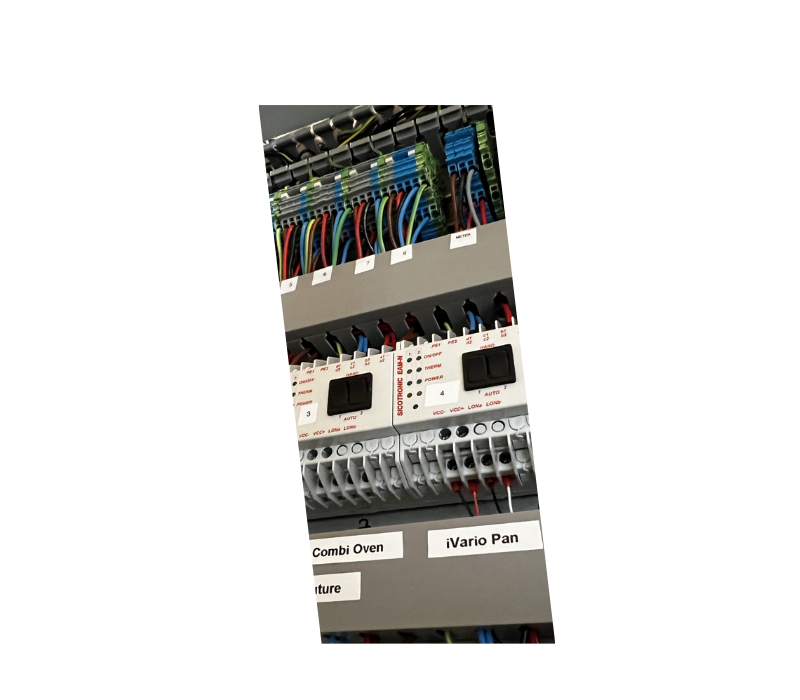

Every time a device requests power, it sends a signal to the Sicotronic-control module. The system monitors the kitchen's entire energy requirements in real time. If free capacity is available, the power is provided immediately. If not, the heating process in the appliance is paused for a few seconds until capacity is available again.

As these delays are extremely short and targeted - and are only applied to heating elements - this has the following consequences No noticeable effects on the cooking result. For appliances with preheating cycles, the system only starts load management when the target temperature has been reached to ensure full functionality.

Sicotronic also increases operational efficiency. Thanks to available usage data, you can:

-

Identify appliances with high energy consumption

-

Optimise deployment plans

-

Reduce energy waste

-

Analyse device usage times and plan maintenance

-

Determine actual cooking vs. standby times

All these functions help, Reduce operating costs, which Extend the service life of the devices and a More efficient, more sustainable kitchen to operate.

FAQs

Blank

What can we connect?

-

- All commercial kitchen appliances with the DIN18875 interface

-

Canteen appliances

-

Combi steamer

-

Induction devices - subject to approval by the manufacturer, as not all induction systems can be optimised

-

Commercial laundry appliances

-

Dishwashing technology - dishwashers, glasswashers and utensil washers

-

Hot counters and warming cabinets

-

Ventilation systems - depending on design and cabling

-

Air conditioning systems - depending on design and cabling

-

Treatments in sauna and spa areas

-

Charging stations for electric vehicles

-

Swimming pool heaters

-

Water boilers - general hot water systems

-

Other electrical devices that can be controlled via simple on/off relays - depending on the connected load and the ratio of potential savings to hardware costs

What cannot be connected in commercial kitchen equipment?

-

Coffee machines

-

Walk-in cold storage and freezer rooms

-

General refrigerators and refrigerated counters

-

Salamander grills / height-adjustable grills

What are the installation requirements for the system?

- Depending on the system size - usually a control cabinet. Typically 1200x600x300 mm (H × W × D), larger enclosures are used for larger systems.

- Control cables 7×1.5 mm² each, laid from the control cabinet to each device connected to the system. The cables are installed in a suitable cable duct - depending on the customer and/or project specifications.

- Current transformers and measuring transducers in the building's power supply

- A broadband data connection facilitates commissioning and enables firmware updates. Both the ZE6000 and ABM2020 systems can be operated via a simple web interface - with an optional cloud connection if required.

What is the difference between intelligent peak load optimisation and load shedding systems?

- Intelligent peak load optimisation from Sicotronic, for example, does not require a priority list for the connected appliances, so the kitchen can be used flexibly without restrictions.

- Thanks to full utilisation of the Sicotronic interface (DIN18875) in the kitchen appliances, the system knows the status of a connected appliance at all times and can switch accordingly.

- With load-shedding systems, the switching times are much longer and this has a negative impact on the cooking process.

What is the average service life of the system?

Sicotronic systems are designed for a service life of over 20 years - many systems of older types such as 3096, ZE4000, ZE5000 or ABM1010 are still in use today, often for as long as the kitchen itself and beyond.

Does the system really need to be hard-wired?

Yes, as a voltage is transmitted from the devices connected to Sicotronic to the intelligent switching technology, this voltage in the fixed cabling basically serves as a communication protocol to carry out the switching process controlled by the software programme.

What power supply does your system require?

We need 1x 230V 16A for our power supply unit

Which system suits me - ABM2020 or ZE6000?

- This is determined by analysing the device list and according to individual requirements.

Can I operate a system without the Internet?

- This is possible because all relevant functions take place locally. The connection to the Internet is necessary to be able to carry out remote maintenance functions.

Can Sicotronic also be retrofitted in existing kitchens?

-

Retrofitting is technically possible without any problems. The only requirement is that the kitchen appliances have the Sicotronic interface in accordance with DIN 18875 and that a 7×1.5 mm² control cable can be laid from the appliances to the electrical distribution board.

Can the system also measure and display PV systems and CHP units?

Yes, the SICOTRONIC energy management system (e.g. with the ZE6000) supports up to 5 separate measurements. This means that, in addition to consumers, energy producers such as photovoltaic systems and combined heat and power plants (CHP) can also be directly recorded, displayed and included in the control/optimisation.

How are multiple feeds taken into account?

Several feed-ins can be recorded in parallel and intelligently combined. The system combines up to 5 separate measurements into a total output, which is then taken into account as total energy in the control and optimisation.

In the extended premium software of the ZE6000, it is also possible to define up to 5 individual limit values for individual energy circuits or distributions. This allows different areas to be monitored and controlled in a targeted manner.

I have several projects with kitchens. Can I monitor these centrally?

Yes, the SICOTRONIC energy management system enables centralised monitoring of multiple sites and projects. Relevant measurement and control data can be securely provided via a REST API and integrated into your own visualisation systems, dashboards or control stations.

I have cold storage rooms - can I monitor them and view temperature curves?

Yes, the SICOTRONIC energy management system supports the integration of continuous temperature monitoring. Cold rooms can be connected directly via an additional module with PT100 inputs.

The temperatures are continuously recorded, saved and displayed graphically as a progression so that deviations can be recognised and documented immediately.

If limit values are violated, an email can be sent directly to any recipient.